- overview

- Our product technology

- Our services

OEM-Contract Manufacturing for Optimal Production-processes

Faeth Group is your reliablepartner for OEM contract manufacturing. We adopt your production–, quality and documentationprocesses, while you retain the supervision of the design, the development and the marketing. Within the scope of the OEM contract manufacturing we confect the components, the group of components, or complete products, according to your individual requirements and specifications. By close collaboration, your profit is guaranteed by our first-class production capacities and by our know-how, in order to produce your required products.

Cost-Savings

You will get the chance of realizing your cost-savings, by outsourcing your business-process to our company. Our company comes with a high in-house production depth and with efficient technologies, leading to shortened cycle times, to better resource provisioning and to better economies of scale, finally leading to a reduction in production costs.

Quality Assurance

Our cleanroom facilities offer stable and controlled conditions, allowing precise assembly and integration of the components This fact leads to a higher precision and consistency regarding the production of the systems, especially if highly precise surroundings, as in the semiconductor industry, are required.

High Purity

Accurate air quality supervision with clean precise checking of particles in cleanrooms is essential, for keeping the purity of the produced systems on a high level. This ensures that no particles may end up in the systems, influencing their performance or even their reliability.

Precision and Accuracy

Our cleanroom facilities offer stable and controlled conditions, allowing precise assembly and integration of the components This fact leads to a higher precision and consistency regarding the production of the systems, especially if highly precise surroundings, as in the semiconductor industry, are required.

Flexibility and Scalability

Contract manufacturing allows companies to flexibly adapt production to the market demand. If required, you may increase or reduce your production volumes without having to make long-term investments in your own production facilities.

Time Saving

By cooperating with Fäth Group, you can significantly shorten your production times. We already have the necessary resources, facilities, and know-how. Rely on our experience and you will benefit from a smooth and effective cooperation.

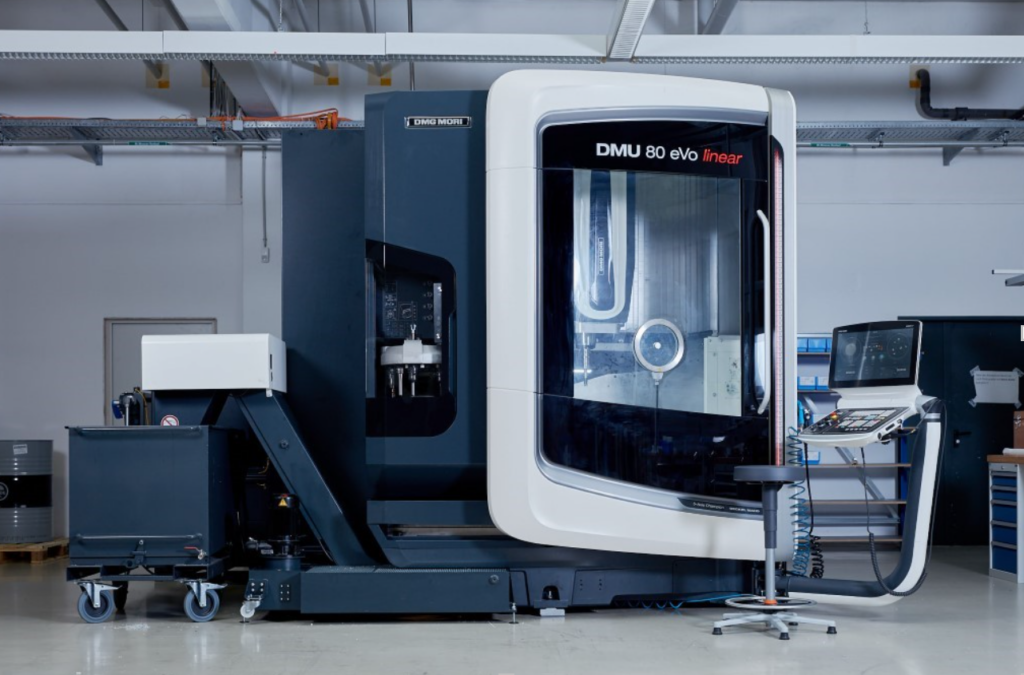

CNC Machining

(Computerized Numerical Control): By using our CNC technology, we enable the precise machining of workpieces by the means of computer-controlled machine tools. Thanks to our CNC lathes and milling machines, we produce complex components. Experience the power of precision with our CNC machining.

Plastics Manufacturing

Our plastics manufacturing facility offers a wide range of services for plastic materials, both in our workshop and in our Class 100 clean room. Learn more about our main manufacturing processes.

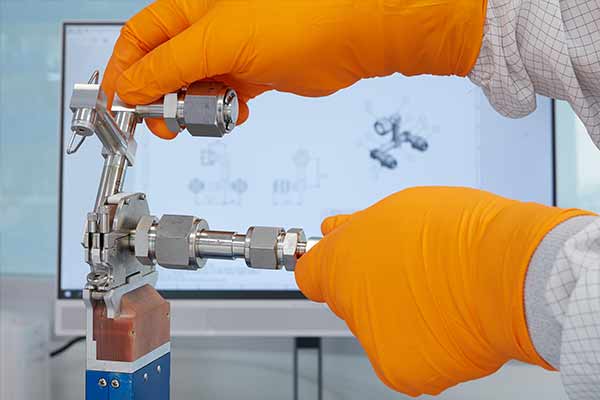

Stainless Steel Production

In our workshop or class 100 clean room, welding and assembly services such as GTWA Orbital & TIG for stainless steel fabrication are available. Learn more about our manufacturing services and let us convince you of our offerings.

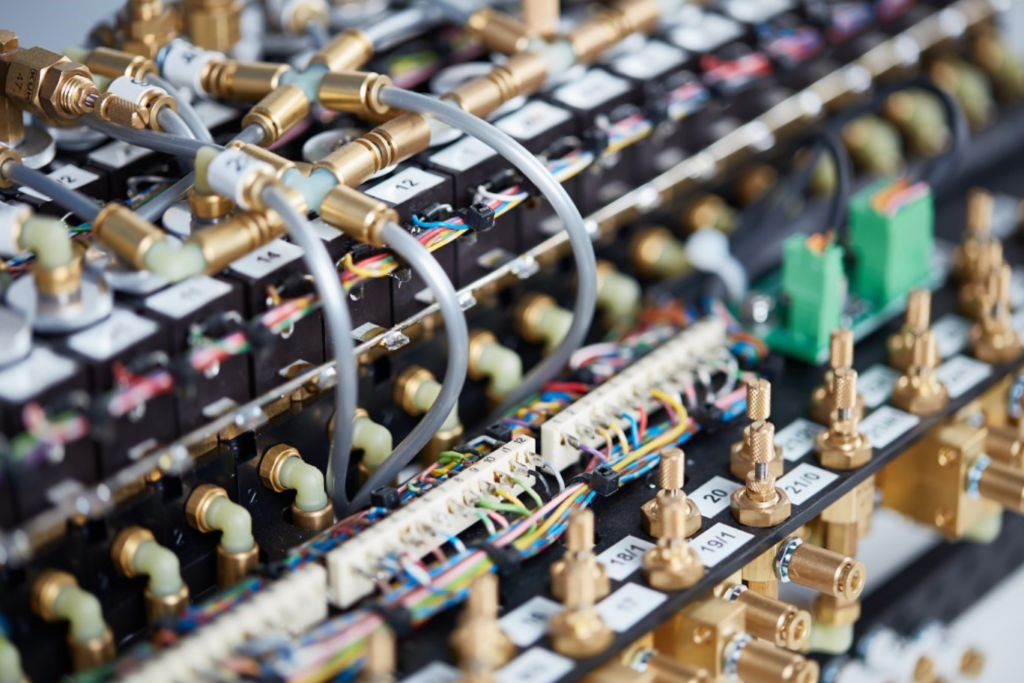

Electronics Manufacturing

As a manufacturer of electronic components and control cabinets, we use a variety of technologies in the OEM process to produce high-quality products. Learn more about the main technologies used in our manufacturing.

Clean Room Production

By combining our plastic and stainless-steel manufacturing capabilities with ISO 6 and ISO 7 cleanroom classifications, we can produce high-quality products that meet the requirements and standards of your industry. We strive to ensure quality, precision and customer satisfaction at every stage of our manufacturing processes.

Production planning

A detailed production plan is developed to manufacture customer components and systems according to requirements.

Procurement of Materials

As an experienced partner, we take care of the procurement of the required materials for carrying out the production. This includes the purchase of raw materials, components and other necessary parts.

Manufacturing

You, as our valued customer, can rely on us to implement your specifications and designs with the highest precision and expertise. This may include the machining of individual parts, the integration of fluidic and mechatronic solutions, or other specific manufacturing processes.

Quality Assurance

We implement quality control procedures to ensure that manufactured customer components and systems meet the required standards and specifications.

Delivery

Our company is responsible for timely delivery of the produced goods to the customer, according to the previously agreed conditions. Through our implemented quality control procedures, we ensure that all customer components and systems meet the given standards and specifications. Thus, we ensure that our customers always receive high-quality and reliable products.

Customer Support

Our reliable customer support is available around the clock to efficiently perform maintenance and service tasks. In order to allow you to fully focus on your core business, we also offer an optional on-call service. This ensures even faster response times and more efficient issue resolution whenever you need us. With this offering, we aim to ensure that any challenges in your operations are addressed and resolved without delay, ensuring the continuity and efficiency of your business.

You may also find these topics interesting

Special plant and special purpose machinery manufacture

Faeth Group: Your partner for complex special plant and special machine construction – from the first consultation to the complete installation.

Gas support systems

Experience the innovative Gas Support Systems by Faeth Group for the industry, pharma & lab – perfectly adapted to your requirements.

Chemistry support systems

Increase reliability & occupational safety in your operation with our chemical support systems. Discover the advantages now!