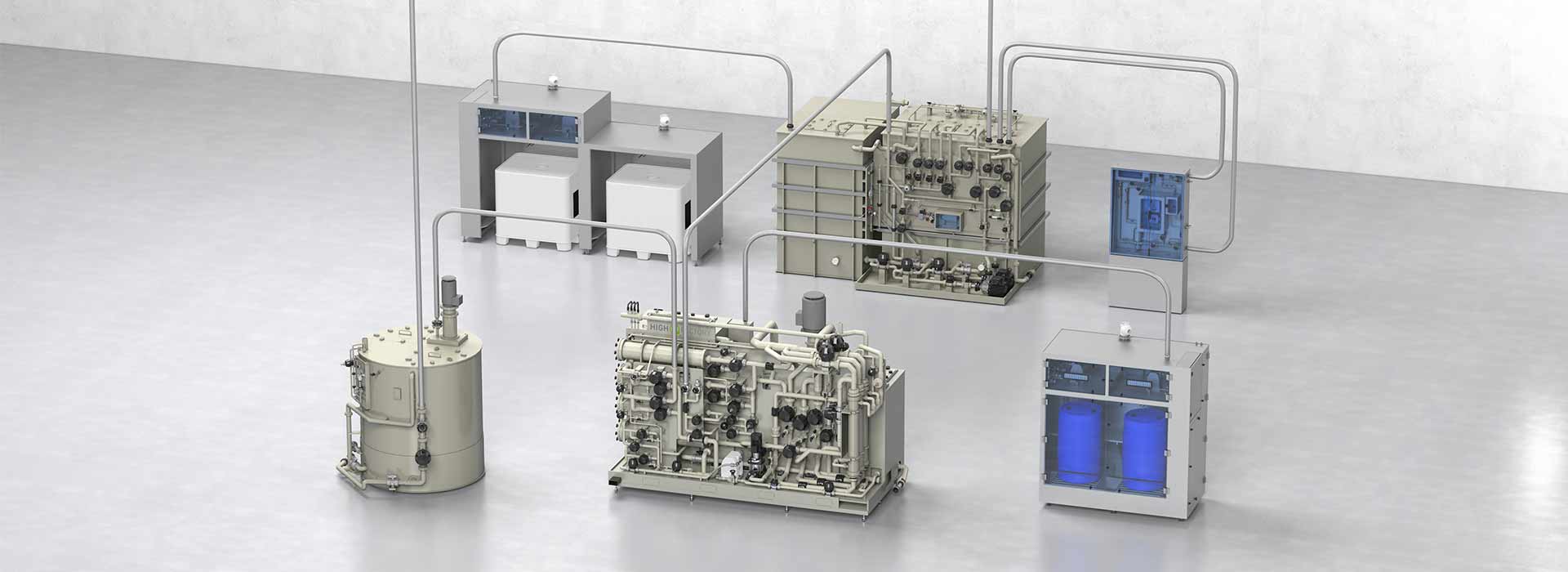

Recycling plants for the recovery of slurry, water and of valuable raw materials

Faeth Group was the world´s first company developing a patented recycling plant, enabling the recovery of ultrapure water and chemical raw materials by the ultrafiltration process. A mixture of wastewater and chemicals is fed to the recycling plant. By the help of several complex filtration and ultrafiltration stages, the mixture of water and chemicals is separated and can be reintroduced into the production process. Such a process is trendsetting and environmentally friendly in the semiconductor industry.

Re-use & Quality Improvement

The patented recycling plant offers the opportunity to recover and re-use the utilised materials. Resources are thus completely exploited. The quality standards of the chemical raw materials are maintained by the recycling process.

Resource-efficient by Recycling Quota

The re-use of chemical raw materials and process water (permeate) results in significant savings in the production process. Thanks to a recycling rate of up to 85%, only 15% of new raw materials need to be added. This significantly reduces the need for raw materials.

Protection of Water Resources

This recycling plant offers an important contribution to protecting the environment. Harmful nanoparticles are filtered out of the wastewater and this provides a better water quality. The reduced consumption of non-renewable raw materials saves important and valuable resources.

Cost Savings due to Backflushing Processes

The patented and self-cleaning backwashing process of the ultrafiltration modules leads to a significantly longer lifetime of the very cost-intensive filter elements. This pushes the cost efficiency of the entire system.

Compact Recycling Module 1UF

The Compact Recycling Module 1UF HighQ for an average throughput of 1.7 m³/h offers advanced, ecological and at the same time high-quality process solutions for the semiconductor industry. The focus of this Compact Module with an ultrafilter is on the recovery of ultrapure water and chemical raw materials by an ultrafiltration process. The entire process is characterized by a high level of efficiency and quality, while increasing productivity and respect for the environment.

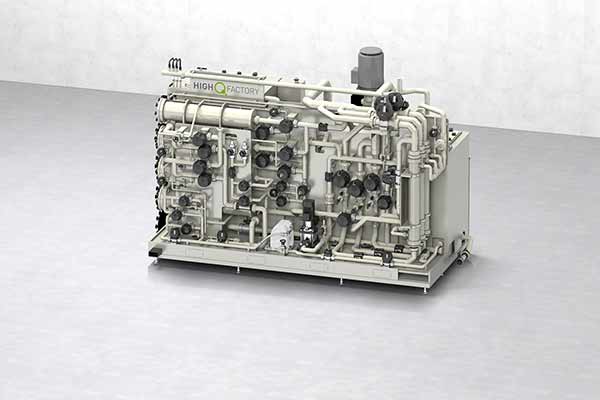

Recycling Module 3UF

With an average throughput of 5.4 m³/h, the Recycling Module 3UF HighQ offers a highly progressive and at the same time a high-quality process solution for the semiconductor industry. This module with its three ultrafilters focuses on the recovery of ultrapure water and on the recovery of chemical raw materials through an ultrafiltration process. This perfect use of resources, as well as a considerable cost efficiency and protection of the environment by saving resources, characterizes this entire process.

Recycling Module 8UF

The Recycling Module 8UF HighQ is suitable for environmentally friendly and highly innovative process solutions in the semiconductor industry with a high throughput of 9.0 m³/h. This module with its eight ultrafilters focuses on the recovery of ultrapure water and of chemical raw materials by an ultrafiltration process. The perfect use of all resources and the concurrent increase in productivity characterize the entire process.

You may also find these topics interesting

Special plants and special mechanical engineering constructions

Fäth Group: Your partner for complex special plant- and special mechanical engineering construction – from the first consultation to the complete installation.

HighQ

The future of the semiconductor industry is here to found: Fäth Group’s patented recycling plant for environmentally friendly slurry raw material recovery!

OEM contract manufacturing

Increase your productivity with our OEM contract manufacturing. Please learn more about our matching solutions!