- OVERVIEW

- APPLICATION AREA

- Our products

- Equipment features

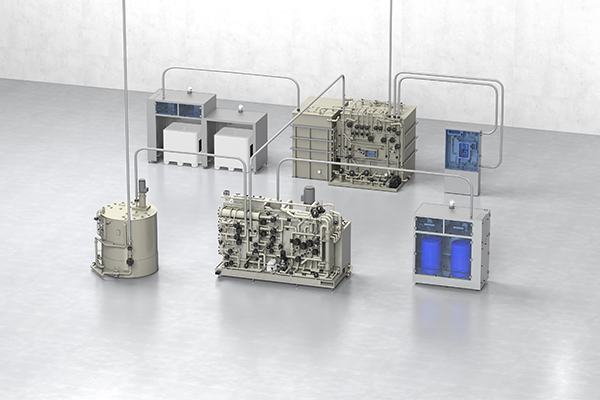

Innovative Solvent Transfer and Dispense Module for the Industry

Solvent Transfer and Dispense Module are systems specially developed by Faeth Group to enable the safe and efficient handling of solvents within the industry. Solvents are liquid chemicals, widely used in many industries, including semiconductor manufacturing, pharmaceuticals, paint and coatings, chemical manufacturing, and others. For this purpose, solvent transfer and dispense module allow a more accurate dosing and supply of solvents, which is of a great importance in many applications. Systems may also be equipped with various safety devices such as leakage detection systems, flame detectors, pressure monitoring devices and extinguishing equipment to ensure safe handling of flammable or hazardous solvents.

Efficiency Increase

A well-organised solvent supply process allows the solvents to be provided safely and efficiently. This leads to an optimized use of resources and to a smooth flow of request- processes.

Cost-Savings

An effective system may help to achieve efficient inventory management by a targeted consolidation of purchases and negotiation of volume discounts, thus resulting in immediate savings.

Quality Assurance

The system allows tracking and controlling the amounts of solvent consumed. This facilitates the avoidance of supply of potential bottlenecks at a good time, ensuring the safety and reliability of supply processes.

Time Saving

An efficient system reduces waiting times and delays in production processes and it helps to increase productivity.

Traceability and Trackability

The system allows tracking and controlling the amounts of solvent consumed. This facilitates the avoidance of supply of potential bottlenecks at a good time, ensuring the safety and reliability of supply processes.

Solvent Transfer and Dispense Module: Specialised systems for the disposal of chemicals

The system offer a wide range of specialised configurations, specifically designed for solvent handling, storage and distribution.

Solvent Tanks

Specifically, designed tanks are used for the safe storage of solvents. These tanks are often made of stainless steel or of special conductive plastic materials, and their own safety features, such as pressure monitoring and level measurement.

Pumps

High quality pumps are deployed for pumping the solvents. Depending on the requirements, different types of pumps can be used, including gear pumps, diaphragm pumps or centrifugal pumps.

Pipings

Special piping systems are installed for safely and efficiently distributing solvents throughout a plant. These pipelines are often made of high-quality materials, such as stainless steel or special plastics, designed and constructed for maintaining solvent purity and for avoiding pollution.

Valves and Controls & Instruments

A variety of valves, controls and instruments are used in solvent supply systems for regulating the solvent´s flow and control. Examples include shut-off valves, check valves, flow meters, and pressure regulators.

Monitoring and Control Systems

Modern solvent supply systems often include advanced monitoring and control technologies. These include sensors for monitoring levels, pressures and temperatures, as well as control units which can automate and monitor plant operation.

Safety Precautions

Solvent supply systems are equipped with various safety features for minimising accidents and hazards. These may include safety sensors, alerts, fire suppression systems and further safety equipment.

Standard Functions

- For holding 60L to 1000L, drums or IBC’s may be placed inside the cabinet, or externally

- Fully automatic pump switching function for an interruption-free feed of chemicals

- Automatic system shutdown by hardware safety interlocks

- Pressure monitoring and regulation of the supply line, ensuring a constant pressure at the point of use

- Centrifugal pump for high flow applications

- Redundant pumps and filters possible

- Automatic pump and filter venting, if required

- Manual flushing and cleaning of the system

- Monitoring of filter service life via differential pressure monitoring, upstream and downstream of the filter

- Nitrogen overlay of the solvents in the drums or containers, if required

- UPW or UN2 spray gun

- Additional pressure sensors for auxiliary media within the pneumatic system

Control Panel

- Siemens SIMATIC S7 series PLC

- Siemens SIMATIC Comfort Panel HMI

- User authorization and password protection HMI

- Multilingual operating instructions on the HMI

- Manual operation of pneumatic valves

- Linking with a monitoring and

- Data acquisition system to control the system

- Access for service and maintenance via remote control module

Safety Functions

- Insulated process and electrical casings

- CDA flushing function of the electrical casing

- Audible and visual alerts and warnings

- Local and remote EMO (Emergency Off) detection of exhaust gas flow

- Leakage detection in the casing

- Door locking system

- Failure Mode and Effect Analysis (FMEA)

- Fire detection

Options

- Vibration dampers, stroke counter and leakage detection for diaphragm pumps

- Chemical recirculation via ring-line

- Temperature monitoring

- Daily tank capacity up to 2000 l inside the cabinet

- Automatic chemical quality analysis during delivery (optional online measurement technology)

- Day-tank housing

- High-precision radar sensor for level monitoring of the day-tank

- Measurement of pressure and flow at pump outlet

- Consumption monitoring

- Automatic system flushing and cleaning

- Platform scale for online level-monitoring

- Fire detection and extinguishing systems

You may also find these topics interesting

HighQ

The future of the semiconductor industry is here to find: Faeth Group’s patented recycling plant for environmentally friendly slurry raw material recovery!

Gas support systems

Experience the innovative Gas Support Systems by Faeth Group for the industry, pharma & lab – perfectly adapted to your requirements.

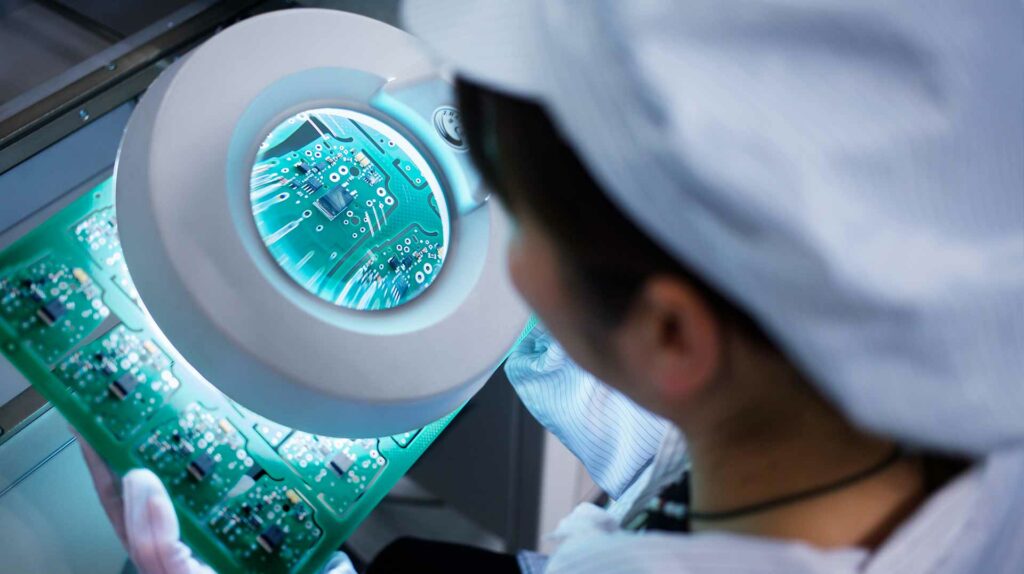

OEM Contract Manufacturing

Increase your productivity with our OEM contract manufacturing. Learn more about our matching solutions!