Recycling systems for the recovery of slurry,

water, and valuable raw materials.

Fäth Group was the world´s first company developping a patented recycling plant, enabling the recovery of ultrapure water and chemical raw materials by the ultrafiltration process. A mixture of wastewater and chemicals is fed to the recycling plant. By the help of several complex filtration and ultrafiltration stages, the mixture of water and chemicals is separated and can be reintroduced into the production process. Such a process is trendsetting and environmentally friendly in the semiconductor industry.

Recycling Modul

| HighQ® Compact Modul | 1.0 – 2.4 m³/h |

| HighQ® Recycling Modul 2 UF | 2.4 m³/h |

| HighQ® Recycling Modul 4 UF | 5.6 m³/h |

| HighQ® Recycling Modul 6 UF | 8.4 m³/h |

| HighQ® Recycling Modul 8 UF | 12 m³/h |

Peripheriemodul

| HighQ® pre- and fine filter module | |

| HighQ® Mix & Transfer Module | |

| HighQ® Wastewater Buffer Tank | |

| HighQ® Permeate Tank | |

| HighQ® Recirculation Tank | |

| HighQ® Analyse Modul | |

| PURAS® Original Slurry Supply System | |

| PURAS® Chemical Supply Module | |

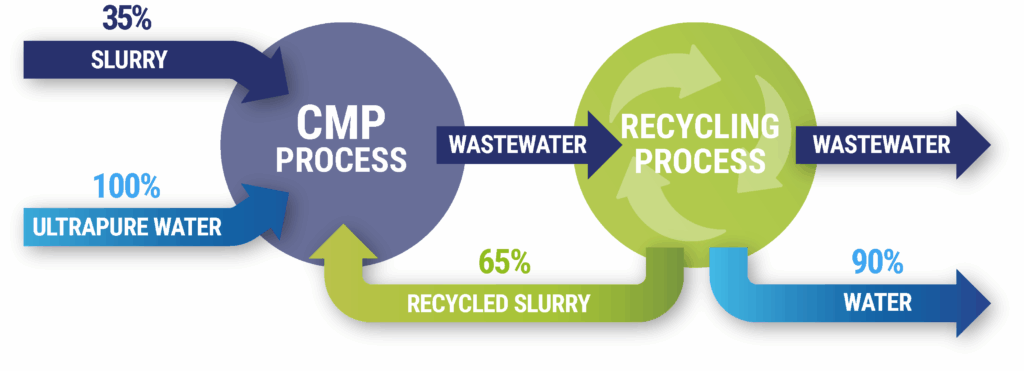

Process Overview: HighQ® Slurry Recycling Systems

Re-use Quality Improvement

The patented recycling plant offers the opportunity to recover and re-use the utilised materials. Resources are thus completely exploited. The quality standards of the chemical raw materials are maintained by the recycling process.

Resource-efficient by Recycling Quota

The re-use of chemical raw materials and process water (permeate) results in significant savings in the production process. With a recycling rate of up to 65%, only 35% of new raw materials need to be added. This significantly reduces the need for raw materials.

Protection of Water Resources

This recycling plant offers an important contribution to protecting the environment. Harmful nanoparticles are filtered out of the wastewater and this provides a better water quality. The reduced consumption of non-renewable raw materials saves important and valuable resources.

Cost Savings due to Backflushing Processes

The patented and self-cleaning backwashing process of the ultrafiltration modules leads to a significantly longer lifetime of the very cost-intensive filter elements. This pushes the cost efficiency of the entire system.

More Interesting Topics

Membrane pilot plant

Compact membrane pilot plant for microfiltration in cross-flow operation. Ideal for trials, scale-up and membrane evaluation under real conditions.

Production membrane plant outside/in:

Sustainable treatment of even complex grinding wastewater – state-of-the-art membrane technology saves fresh water and ensures stable filtrate quality.

Chemical Support Systems PURAS®

PURAS® chemical supply systems provide safe and efficient chemical handling, optimize processes, enhance workplace safety, and minimize the risk of accidents.