Planung & Engineering

Fäth Group designs piping systems precisely according to your requirements – tailored to purity class, chemical resistance, pressure, flow rate, and durability. Using CAD planning software, isometric views, pipe lists, and carefully selected materials, we integrate state-of-the-art measurement and control technology, including level monitoring and pressure supervision.

Prefabrication & Installation

High-quality materials such as PVDF, PFA, and stainless steel are used for piping systems. Depending on the application and industry, pipelines are connected with Flaretec fittings, orbital or TIG welding, ensuring compatibility with different media, purity levels, and process requirements.

Qualification & Commissioning

Our installations are carried out with the highest precision on-site, whether in existing facilities or new constructions. Every step of the assembly is fully documented. Commissioning is conducted according to strict internal testing criteria and customer specifications.

Maintenance & Servicing

Even after project completion, we provide long-term support. Through hook-up, maintenance, and service contracts, we ensure the uninterrupted operation of your systems. Gas detection systems and automated shutdown mechanisms guarantee maximum safety.

Reference Projects

Factory Planning for Piping Systems

Whether piping, hook-up, or ultra-pure media supply – from the first concept sketch to turnkey implementation, we create production infrastructures that meet the highest safety and efficiency standards. Digital BIM planning, cleanroom-ready installation, and sustainable supply technology combine cutting-edge engineering with a clear vision for the future.

Ultra-Pure Water Systems

Fäth ultra-pure water systems convert drinking or raw water into high-purity UPW, essential for semiconductor, pharmaceutical, and medical technology applications. Supply pipelines are made of corrosion-resistant materials such as PP-H or PVDF and are designed according to flow rate and operating pressure, creating safe and efficient systems for sensitive high-tech applications.

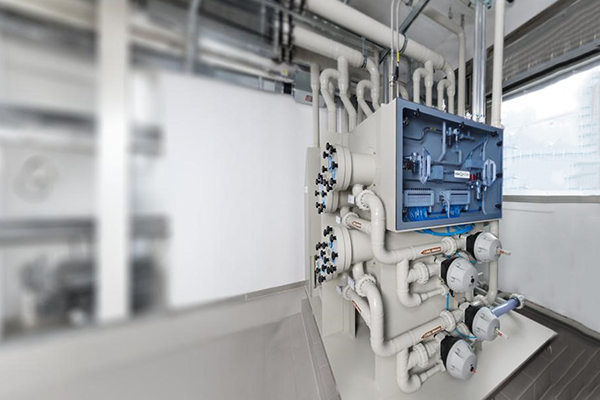

Chemical Filter Stations

Fäth filter stations reliably remove particles, suspended solids, and dissolved contaminants from drinking or raw water. Depending on requirements, sieve, candle, activated carbon, or fine filters are used. Corrosion-resistant pipelines made of stainless steel, PVC-U, or PP-H supply raw water and discharge filtrate and rinse water, designed according to flow rate and operating pressure.

Stainless Steel Piping

Stainless steel piping is considered the backbone of modern industrial pipelines: corrosion-resistant, pressure-resistant, hygienic, and durable. Whether in pharmaceuticals, food, chemicals, or clean rooms, pipes made of 1.4404/316L meet the highest standards, are easy to clean (SIP/CIP), and comply with standards (DIN EN 10357, ASME BPE). Seamless or welded, they ensure sterile processes in sensitive applications.